At the heart of every Grain

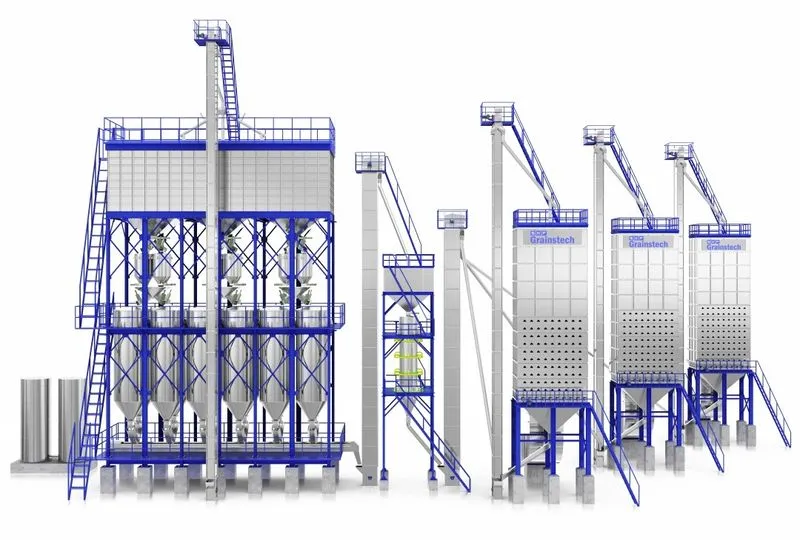

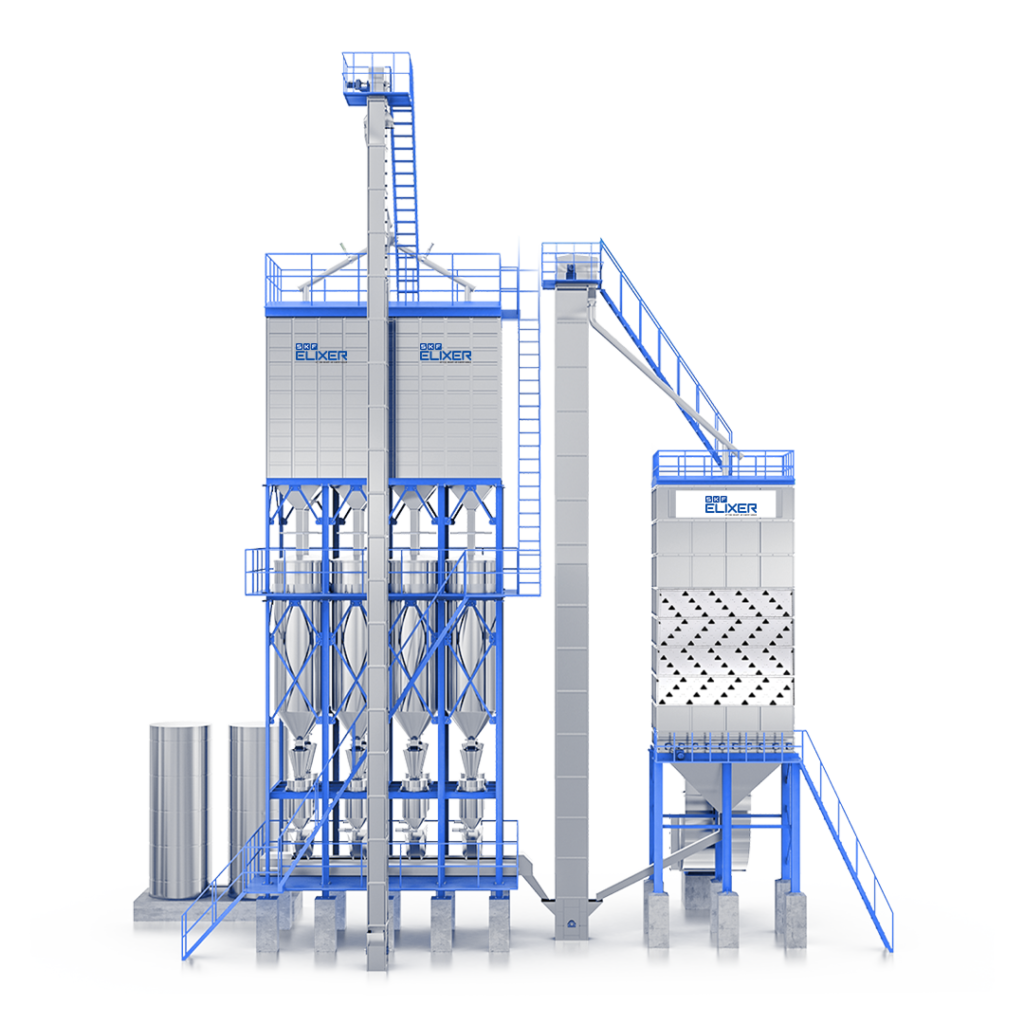

End-to-End Paddy Processing Plant Manufacturer With Complete Turn-key Facility

Established Global leaders in supplying high-end Parboiling plant machinery with over 7000 installations worldwide.

Industry Leaders in Designing & Manufacturing Paddy Processing Systems

From our humble beginnings in 1987 as a rice cooker manufacturer, we have transformed into a globally recognized leader in paddy processing. Leveraging innovation and cutting-edge technology, we have mastered the parboiling and drying processes to deliver exceptional results.

Our Processes

Initial Consultation

We analyze your requirements, production capacity, process type, automation needs, space constraints and provide you with quotation and delivery timeline.

Planning and designing

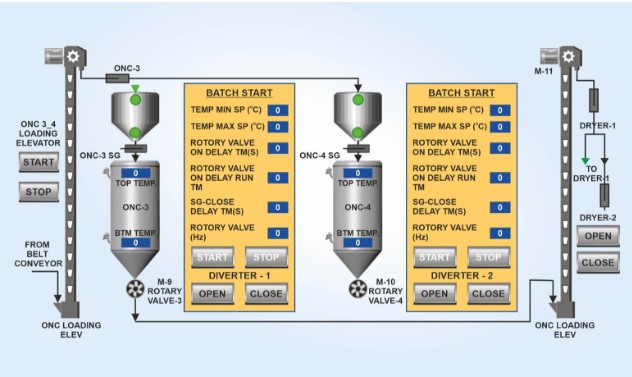

Our engineers create detailed 2D and 3D blueprints, selecting high-quality raw materials and food-grade components for maximum durability and performance efficiency. The design phase includes structural strength calculations, energy efficiency planning, and integration of advanced control systems like PLC and SCADA.

Manufacturing

Fabrication of each components such as soaking tanks, steam chambers, dryers, and heat exchangers, is carried out using precision lasser cutting machine. Each unit undergoes rigorous quality testing, including pressure resistance, temperature control accuracy, dimensional accuracy and material integrity checks.

On-Site Installation & Commissioning

Finished items are transport to site for erection and instalation using nut and bolt systems. Our engineers performs temperature control system calibration, align mechanical components, fine-tune automation systems and conduct dry/wet run trails. A full-scale production test is conducted to verify system performance.

Training & Handover

We provide training and guidance for your staff on plant operations, system controls, automation software and safety protocols- to minimize downtime and enhance operational efficiency from day one.

After-Sales Support & Maintenance

Get continuous customer support and spare part availability. Our service team is equipped to handle troubleshooting, software upgrades, and mechanical repairs to keep your production run smoothly.

Our Processes

Witness enhanced yield, superior grain quality, and adaptability to various rice types through our advanced processing techniques.

1) Introduction of Clean Paddy

Cleaned paddy is fed into the system after removing impurities, ensuring only high-quality grains proceed.

2)Buffer Zone

Paddy is stored within a storage bin, maintaining grain integrity before further processing.

3) Kachi Tank Pre-Steaming

Paddy undergoes pre-steaming in the Kachi Tank at 3-bar pressure to initiate starch gelatinization, softening the husk.

4) Soaking

The grains are immersed and circulated in water at specific temperatures to facilitate even hydration, enhancing the gelatinization process.

5) Belt Conveyor

An automated belt conveyor system transports the hydrated paddy to subsequent stages, ensuring efficiency and minimal handling.

6) Pakki Steaming System

The paddy is subjected to a final steaming at 3-bar pressure to achieve optimal moisture content for the drying phase.

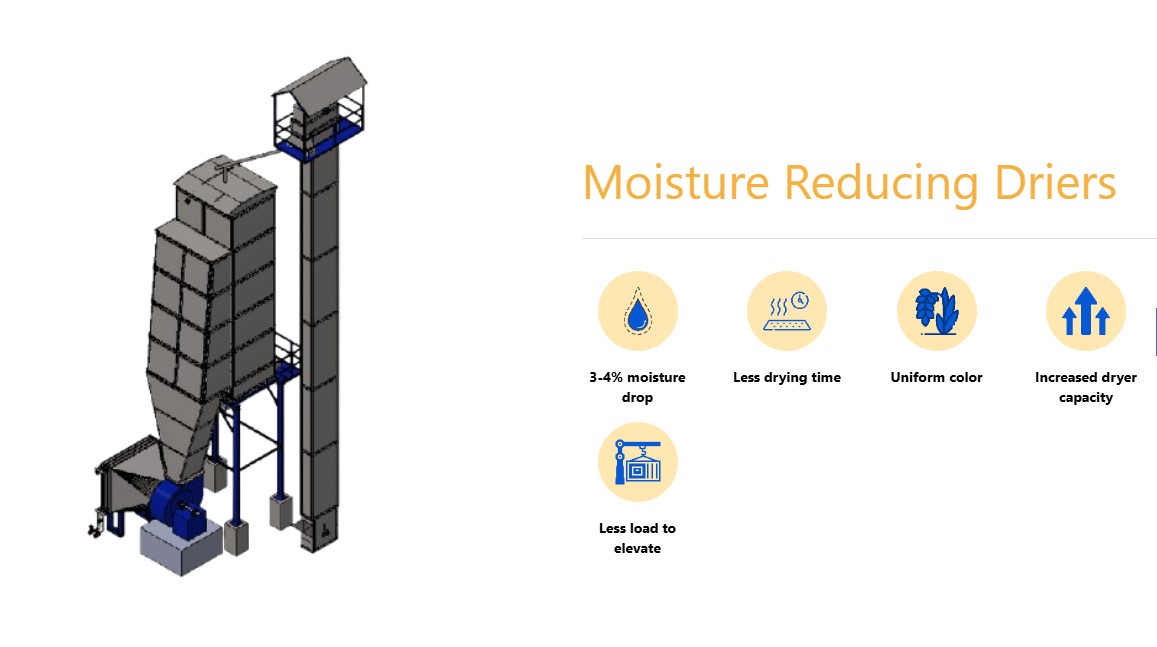

7) Tapered V Dryer

Utilizes a specialized drying mechanism to reduce moisture content from approximately 36%-34% down to 13%-12%, maintaining grain quality.

8) Tempering

Post-drying, the paddy is cooled to room temperature in a controlled environment, stabilizing the grain structure before milling.

9) Rice Milling

The processed paddy is then conveyed to the rice mill for dehusking and polishing, preparing it for market distribution with enhanced grain quality and appearance.

1) Introduction of Clean Paddy

Cleaned paddy is fed into the system after removing impurities, ensuring only high-quality grains proceed.

2) Buffer Zone

Paddy is stored within a storage bin, maintaining grain integrity before further processing.

3) Soaking

The grains are immersed and circulated in water at specific temperatures to facilitate even hydration, enhancing the gelatinization process.

4) Belt Conveyor

An automated belt conveyor system transports the hydrated paddy to subsequent stages, ensuring efficiency and minimal handling.

5) Loading Elevator

The paddy is mechanically elevated to be fed into the next processing equipment.

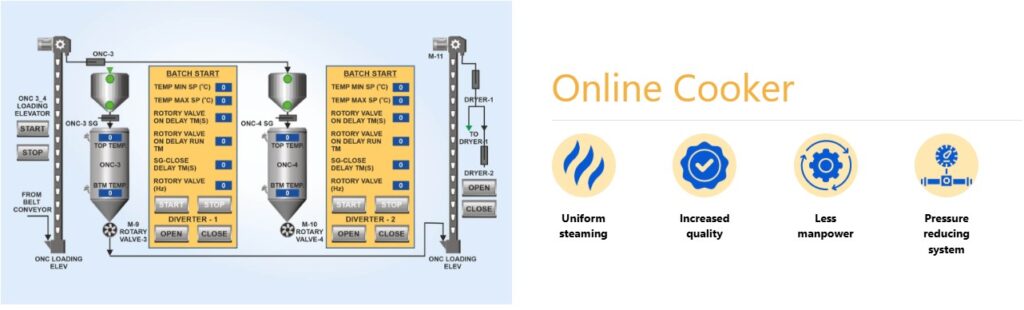

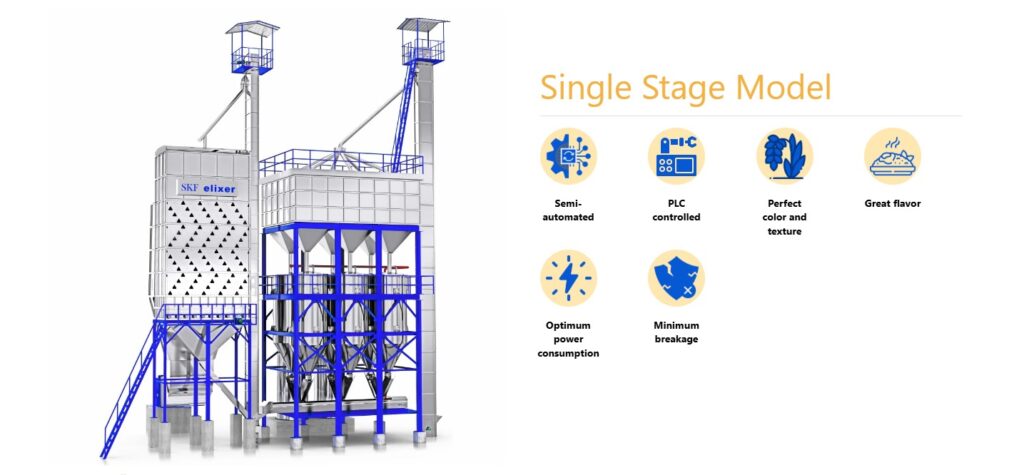

6) Online Cooker:

Here, paddy undergoes high-pressure steaming at 3 bars to enhance flavor, texture, and nutritional value through complete gelatinization.

7) Tapered V Dryer

Utilizes a specialized drying mechanism to reduce moisture content from approximately 36%-34% down to 13%-12%, maintaining grain quality.

8) Tempering

Post-drying, the paddy is cooled to room temperature in a controlled environment, stabilizing the grain structure before milling.

9) Rice Milling

The processed paddy is then conveyed to the rice mill for dehusking and polishing, preparing it for market distribution with enhanced grain quality and appearance.

1) Introduction of Clean Paddy

Cleaned paddy is fed into the system after removing impurities, ensuring only high-quality grains proceed.

2)Buffer Zone

Paddy is stored within a storage bin, maintaining grain integrity before further processing.

3) Soaking

The grains are immersed and circulated in water at specific temperatures to facilitate even hydration, enhancing the gelatinization process.

4) Belt Conveyor

An automated belt conveyor system transports the hydrated paddy to subsequent stages, ensuring efficiency and minimal handling.

5)Loading Elevator

The paddy is mechanically elevated to be fed into the next processing equipment.

6) Online Cooker:

Here, paddy undergoes high-pressure steaming at 3 bars to enhance flavor, texture, and nutritional value through complete gelatinization.

7) Tapered V Dryer

Utilizes a specialized drying mechanism to reduce moisture content from approximately 36%-34% down to 13%-12%, maintaining grain quality.

8) Tempering

Post-drying, the paddy is cooled to room temperature in a controlled environment, stabilizing the grain structure before milling.

9) Rice Milling

The processed paddy is then conveyed to the rice mill for dehusking and polishing, preparing it for market distribution with enhanced grain quality and appearance.

1) Introduction of Clean Paddy

Cleaned paddy is fed into the system after removing impurities, ensuring only high-quality grains proceed.

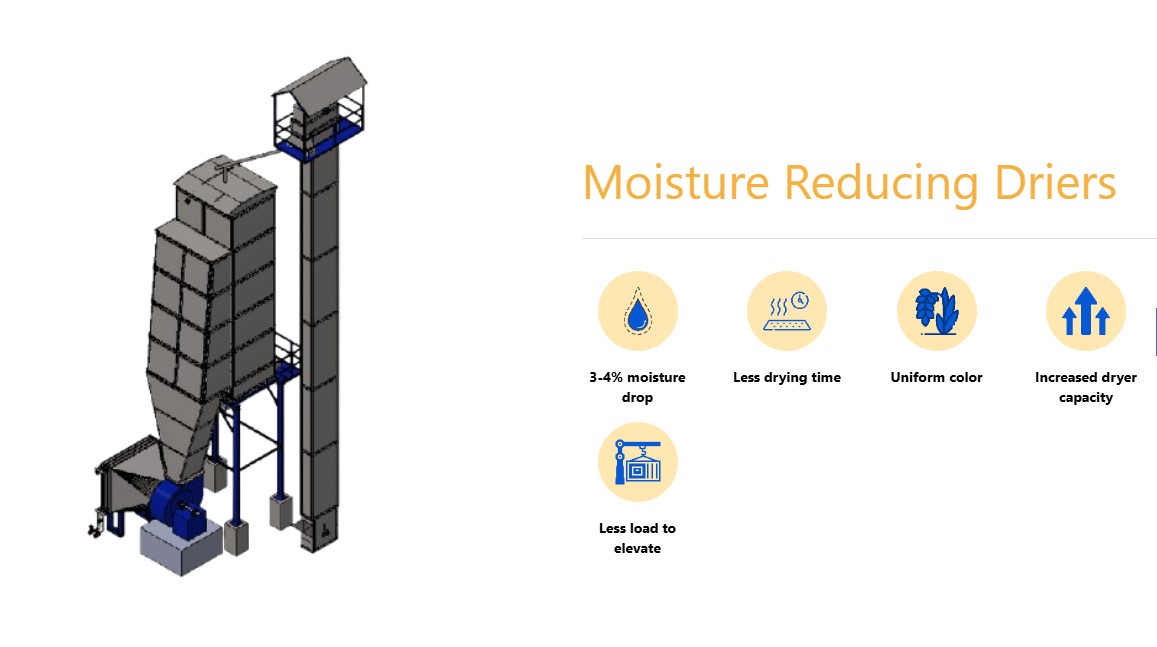

2) Initial Drying:

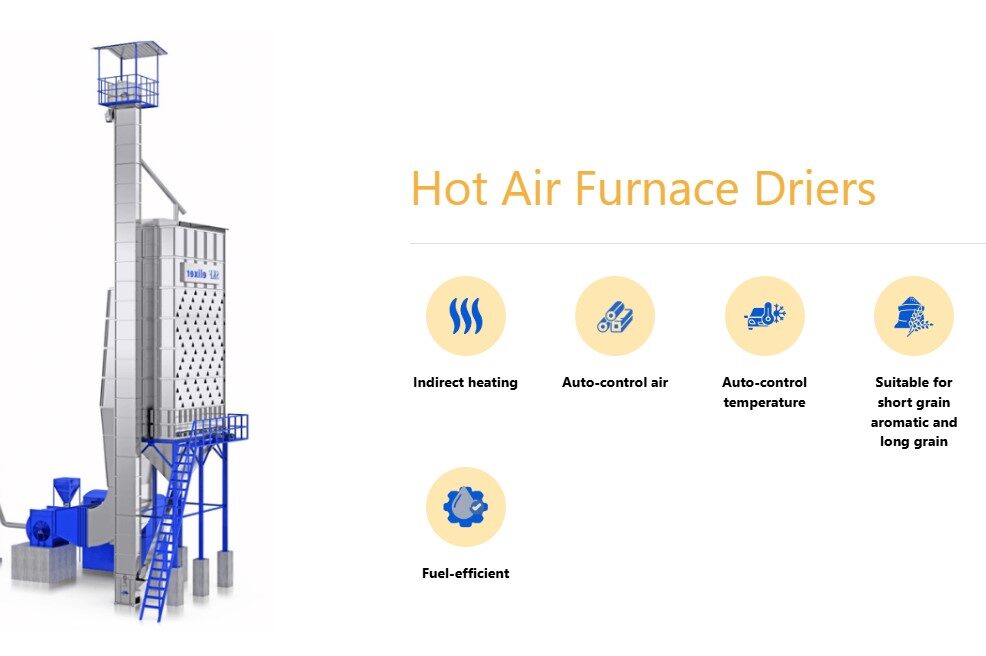

The first drying phase reduces the moisture content from approximately 20% to a lean 10-12%, using specialized dryers designed for uniform moisture removal.

3) Bin Elevator:

An automated elevator system lifts the paddy to storage, optimizing the flow and reducing manual handling.

4)Buffer Zone

Paddy is stored within a storage bin, maintaining grain integrity before further processing.

5) Online Cooker:

Here, paddy undergoes high-pressure steaming at 3 bars to enhance flavor, texture, and nutritional value through complete gelatinization.

6) Resting Bin

After steaming, grains are allowed to rest, absorbing the steam’s effects, which influences color and taste stabilization.

7) Belt Conveyor

An automated belt conveyor system transports the hydrated paddy to subsequent stages, ensuring efficiency and minimal handling.

8) Secondary Drying:

The grains are dried again to adjust moisture from around 36% back to 13-12%, fine-tuning for optimal grain quality.

9) Tempering

Post-drying, the paddy is cooled to room temperature in a controlled environment, stabilizing the grain structure before milling.

10) Rice Milling

The processed paddy is then conveyed to the rice mill for dehusking and polishing, preparing it for market distribution with enhanced grain quality and appearance.

1) Paddy Cleaning:

Harvested paddy is subjected to cleaning processes to remove any foreign material, ensuring quality and purity of the grain.

2) Dryer Elevator:

An elevator mechanism elevates the paddy to the dryer, facilitating the transition to the moisture reduction phase.

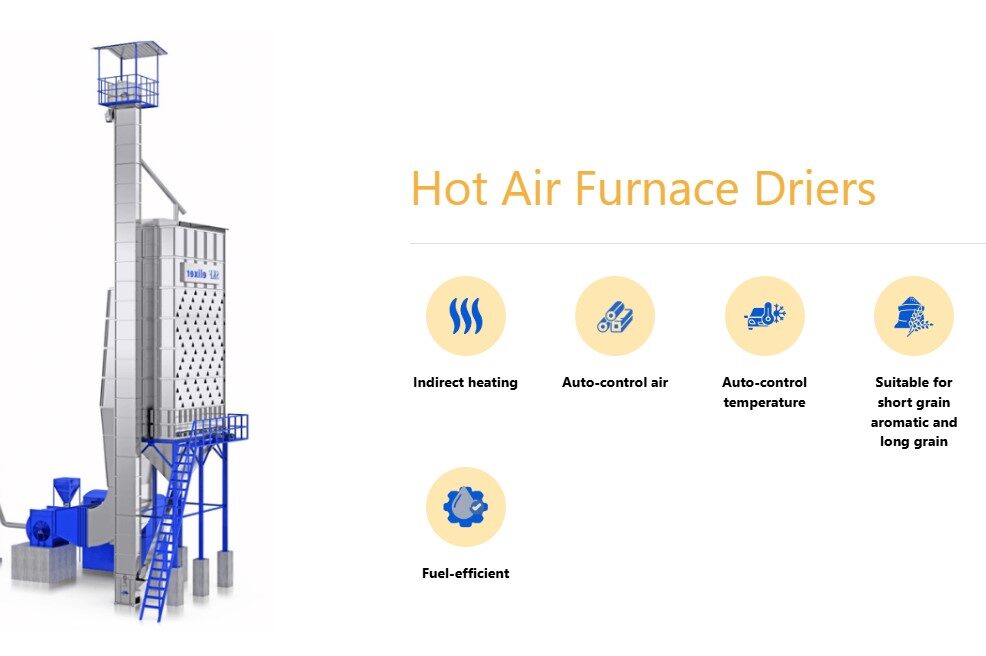

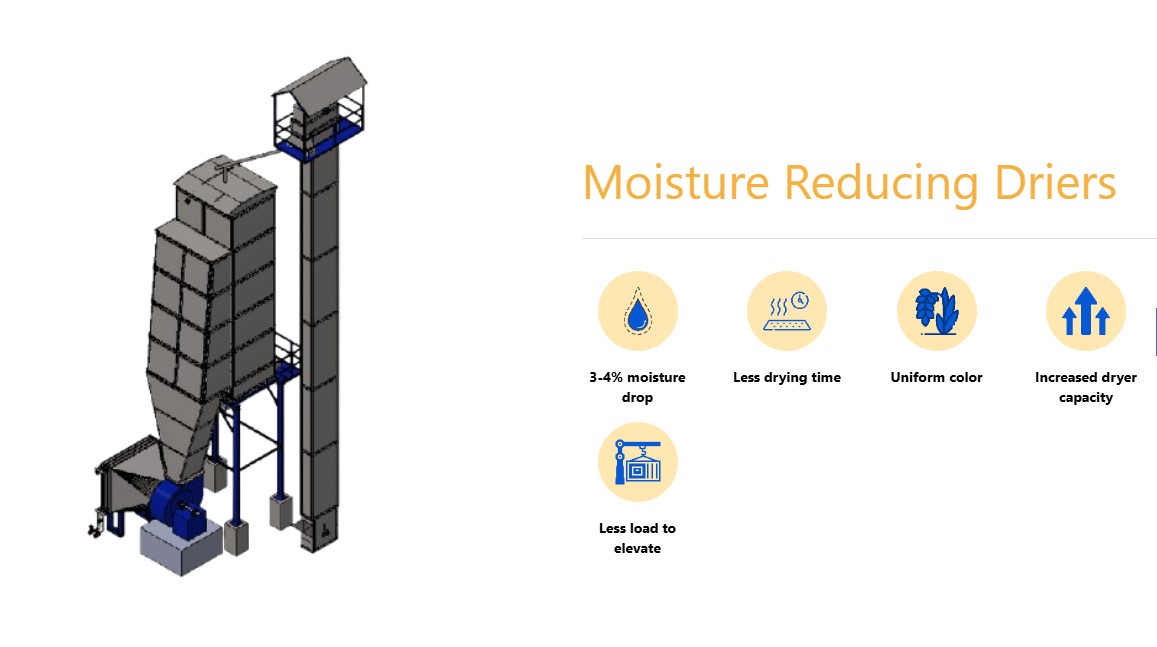

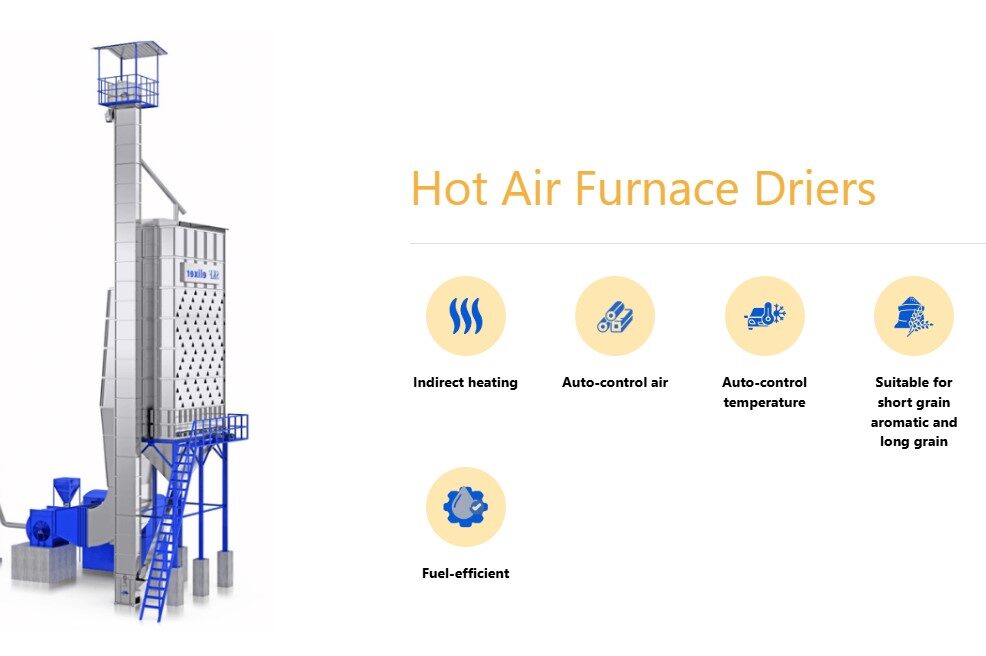

3) Dryer:

The paddy enters a controlled drying environment where moisture is reduced from its initial content to approximately 10-12%. This step is critical for preventing microbial growth, maintaining grain color, and ensuring long-term storage stability.

4) Tempering

Post-drying, the paddy is cooled to room temperature in a controlled environment, stabilizing the grain structure before milling.

5) Rice Milling

The processed paddy is then conveyed to the rice mill for dehusking and polishing, preparing it for market distribution with enhanced grain quality and appearance.

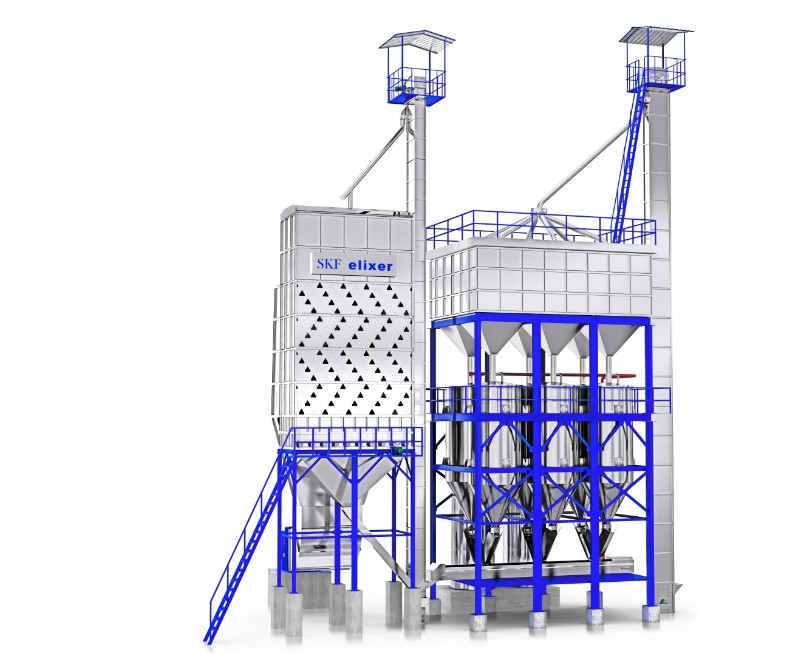

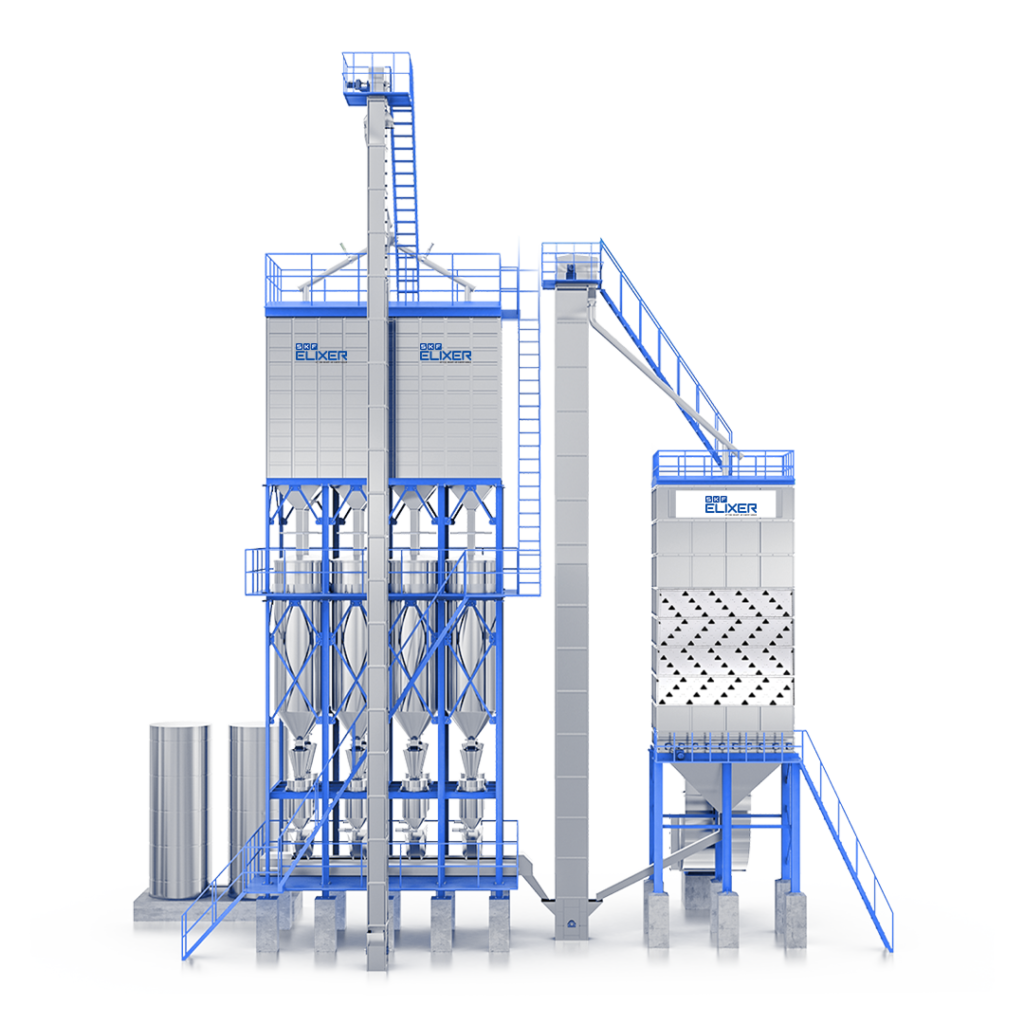

Why choose SKF:

- Pioneers in parboiling, steaming and drying plants.

- An installation base of over 7000 plants in India and abroad.

- Equipment designed for all varieties of paddy and all processes. Complete turn-key solutions including designing, supply, installation and commissioning

- Complete turn-key solutions including designing, supply, installation and commissioning.

- Built of Stainless Steel (SS)

- Runs for >10 years without maintenance cost

- Hot water automation for increasing the productivity

- Effective online cooker achieve automated gelatinization process through PLC control

Paddy Processing Plant Manufacturers & Suppliers

SKF Elixer India Pvt. Ltd manufactures a majority of its components in-house, starting from foundation bolts, blowers, elevators, chain conveyor, heat exchangers and panel boards, thereby enabling control on the quality of inputs and attention to detail.

Input

All raw materials whether its SS sheets or SS/MS items undergo a rigorous incoming inspection based on company’s standard quality plan. These raw materials are sourced from vendors with whom the company has cultivated and built a relationship over several years giving them a significant advantage in terms of quality, price and availability.

Processing

Each order is then split into the parboiling section, drier section and various other components such as blower, heat exchanger, steam chamber and foundation components are put together after a series of processes such as fabrication, cutting, bending, welding and painting. SKF Elixer is one of the few companies in India to use a ‘Bystronic, Swiss base’ laser cutting machine to ensure precise fitment and finish to its products.

Output

The finished items are tested and inspected on, precision, perfection, tensile strength and dimensional accuracy, before they are packed in a partially knocked down condition and transported to the site for erection and installation. The parboiling and drying units manufactured by SKF Elixer use a nut bolt system thereby enabling a quick turnaround time. SKF Elixer is one of the few companies in India to use a ‘Bystronic, Swiss base’ laser cutting machine to ensure precise fitment and finish to its products.

- Watch Video

Take part in the journey of raw paddy with our all-in-one processing system. This video showcases how our integrated approach efficiently handles every step of paddy processing, ensuring the highest quality and yield in rice production.

Our Gallery

Portfolio

Paddy Processing Calculator

Accurately calculate your paddy processing costs and yields with ease!